Our glasses

In the absence of a universally recognized reference standard for testing the safety of paddle court glass, we offer you the possibility of choosing between the following types of glass:

Monolithic tempered safety glass

12 mm thick tempered safety monolithic glass, performance class 1C2 according to the EN 12600 standard, compliant with all current sports regulations and therefore sufficient to obtain certification of the field from the competent sports federation.

We have chosen not to offer 10mm monolithic tempered glass because it is too fragile and does not guarantee a satisfactory ball bounce.

Laminated tempered safety glass

6+6 mm, 8+6 mm and 8+8 mm thick laminated tempered safety glass, performance class 1B1 according to the EN 12600 standard, compliant with all current sports regulations, the requirements of the UNI 7697:2021 standard and the requirements for obtaining the TÜV SÜD Certification Mark.

As the thickness of the glass increases, the probability of glass breakage decreases and the rigidity of the glass wall increases, favoring the rebound of the ball.

We leave it up to you to choose between monolithic and laminated tempered glass. Our advice is to opt for laminated glass, which in the event of breakage completely eliminates the risk of injuries, both serious and superficial, to players and those near the field.

The choice of laminated glass becomes mandatory if, in the event of glass walls breaking, the player is exposed to the risk of falling from a height of 1 meter or more.

Regulatory framework

The correct choice of materials for the glass walls of padel courts is essential to ensure a correct bounce of the ball and to guarantee safety for both users and the structure.

The choice must be made taking into account the building and sports regulations to obtain the necessary building permits for the construction of the courts and their approval by the competent sports federation.

The rapid growth of recent years makes padel a poorly regulated sector. To date, there is no specific reference standard for testing the safety of glass walls of padel courts. However, the operator has de facto civil and criminal liability for the safety of its facilities.

In the event of an accident, the operator is exposed to the risk of criminal prosecution for negligent injuries and must be able to provide concrete evidence of having created all the necessary conditions to guarantee the safety of players, spectators and service personnel.

In this context, the resistance to breakage of the glass walls of the courts and the type of glass breakage are extremely important because, due to breakage, the glass fragments can hit those nearby falling from a height of even more than 3 meters, risking injury and serious aesthetic damage.

International Padel Federation (FIP)

The International Padel Federation (FIP) simply prescribes that the glass used for padel courts must comply with the EN 12150 standard, which is the European standard that specifies the characteristics relating to tolerances, flatness, edge processing, fragmentation and physical and mechanical aspects of thermally tempered monolithic flat glass.

For the classification of glass according to its breaking behaviour, the EN 12150-1 standard refers to the EN 12600 standard (pendulum test).

By quoting the EN 12150 standard without providing any indication on the classification of glass according to the EN 12600 standard, the FIP actually requires that the glass walls of padel courts be made of thermally tempered glass or laminated glass obtained by laminating two or more sheets of thermally tempered glass, but does not provide any indication either on the thickness of the glass or on the performance class.

EN 12150 and EN 12600 standards

The EN 12150 standard is the European standard that specifies the characteristics relating to tolerances, flatness, edge processing, fragmentation and physical and mechanical aspects of thermally tempered monolithic flat glass.

For the classification of glass according to its breaking behaviour, the EN 12150-1 standard refers to the EN 12600 standard (pendulum test).

The EN 12600 standard provides criteria for measuring the performance class of a flat glass sheet when it is hit by a soft body simulating the impact of a human body (pendulum).

The performance class is expressed in the following form: αβφ

α

α is the breaking strength class of the glass, determined by the height of the pendulum drop at which the glass did not break or broke safely:

- α = 1: pendulum drop height 1200 mm

- α = 2: pendulum drop height 450 mm

- α = 3: pendulum drop height 190 mm

The higher the value of α, the lower the resistance of the glass to breakage.

β

β is the type of glass breakage

- β = A: Numerous cracks appear, forming separate fragments with sharp edges, some of which are large.

This is the typical breakage of annealed glass. - β = B: Numerous cracks appear, but the fragments stay together and do not separate.

This is the typical breakage of laminated glass with plastic film interposed. - β = C: Disintegration occurs, leading to the formation of a large number of small, relatively harmless particles.

This is the typical breakage of thermally tempered monolithic glass

φ

φ is the class of protection against the risk of falling into the void

determined on the basis of the maximum pendulum drop height at which the product either did not break or broke into fragments that stay together and do not separate (typical breakage of laminated glass with plastic film interposed), providing a containment capacity that effectively eliminates the risk of the user falling into the void.

- φ = 1: pendulum drop height 1200 mm

- φ = 2: pendulum drop height 450 mm

- φ = 3: pendulum drop height 190 mm

The higher the value of φ, the lower the protection from falling into the void in case of glass breakage.

National Padel Federations

Some National Padel Federations provide more guidance than the FIP. For example:

The Fédération Française de Tennis (FFT) prescribes that the glass walls of the courts be made of tempered glass with a minimum thickness of 10mm (12mm in the case of panoramic courts) or laminated glass with a minimum thickness of 2 x 6mm

The Lawn Tennis Association (LTA), which is the national governing body for tennis in the UK, requires that glass walls be made from 10mm or 12mm toughened glass, making no distinction between monolithic and laminated glass, but states that 12mm toughened glass is preferable as it offers a more solid structure and is preferred by players for its superior rebound characteristics.

The Italian Tennis and Padel Federation (FITP) requires that the glass walls of the courts be made of “monolithic tempered glass with a minimum thickness of 10 mm or laminated glass with a thickness of 6+6 mm.”

National Padel Federations

In some Countries there are local regulations that contain further guidance.

For example, in Italy, the standard UNI 7697 contains the requirement that glass elements of Padel courts be made of laminated safety glass in minimum performance class 1B1 according to EN 12600.

Other Member States, many of which do not yet have a text on the subject, are also considering this standard. The CEN Technical Committee 250 (CEN/TC250) “Structural Eurocodes” is working to make it a European standard related to the Eurocodes.

There is a heated debate in Italy about the mandatory nature of the UNI 7697 standard. It is our opinion that even when compliance with UNI 7697 is not mandatory, its application is a guideline for better construction safety.

Voluntary product certification schemes

There are several strictly voluntary test protocols and product certification schemes developed by independent third-party bodies that, in the absence of a specific reference standard, provide valuable guidance for verifying the safety of padel facilities.

For example, the third-party body TÜV SÜD, internationally renowned for its independence, experience and reliability, has developed a dedicated test protocol that establishes, as a prerequisite for the issuance of the TÜV SÜD Product Certification Mark, that the glass walls of padel courts be made of laminated glass, minimum performance class 1B1 according to EN 12600.

Our recommendations

All in all, in the absence of a specific reference standard, our recommendations are as follows:

Resistance to breakage α

It is definitely worth choosing a glass with resistance class 1 (pendulum fall height 1200 mm). If only to minimize the frequency of glass breakage and the consequent field shutdown.

Fracture pattern β

The use of glass with fracture pattern A, which is typical of annealed glass (numerous cracks forming separate fragments with sharp edges, some of which are large in size), should be avoided at all costs, as the large sharp fragments, falling from a height of even more than 3 meters, could cause serious injuries to those nearby.

Furthermore, the use of this type of glass is not permitted by the FIP or any Local Federation, which would prevent the approval of the field.

The use of glass with fracture pattern C, typical of thermally tempered monolithic glass (disintegration, which leads to the formation of a large number of small, relatively harmless particles), although permitted by sports regulations, eliminates the risk of serious injury but not that of superficial injuries and consequent even serious aesthetic damage that could expose the facility manager to the risk of criminal prosecution for negligent injury. In this case, the existence of more restrictive regulations, although not binding, but issued by institutions and bodies of certain notoriety and reliability such as UNI and TÜV SÜD, could put the manager in the position of not being able to demonstrate that he has created all the conditions necessary to guarantee the safety of players, spectators and service personnel.

Glass with fracture pattern B, typical of laminated glass with an interposed plastic film (numerous cracks, but the fragments remain joined and do not separate), is the only one that completely eliminates the risk of injuries, serious or superficial, and therefore the only one that completely protects the facility manager from criminal proceedings for negligent injuries.

Fall protection class φ

In most cases, the padel court is surrounded by a wide strip of pavement coplanar with the playing surface, which effectively eliminates the risk of falling into the void and makes the class of protection from the risk of falling into the void completely irrelevant.

However, there are special cases in which at least a portion of the glass walls of the field faces a void of 1 meter or more in height.

In such cases, protection from the risk of falling into the void becomes essential, and the choice of glass type becomes mandatory.

In fact, only laminated glass with interposed film guarantees breakage into fragments that stay together and do not separate, and therefore possesses a containment capacity that effectively eliminates the risk of the user falling into the void.

In conclusion, if there is a risk of falling from a height of 1 meter or more, it will certainly be necessary to use laminated glass in performance class 1B1 according to EN 12600.

Weld mesh panels protected by abrasion-resistant profiles

We cover the weld points between the wire meshe and and the surrounding metal frame with a special punched element. This measure prevents the ball from coming into contact with abrasive surfaces and protects the players in the event of contact.

Heat-cured polyester epoxy powder paint

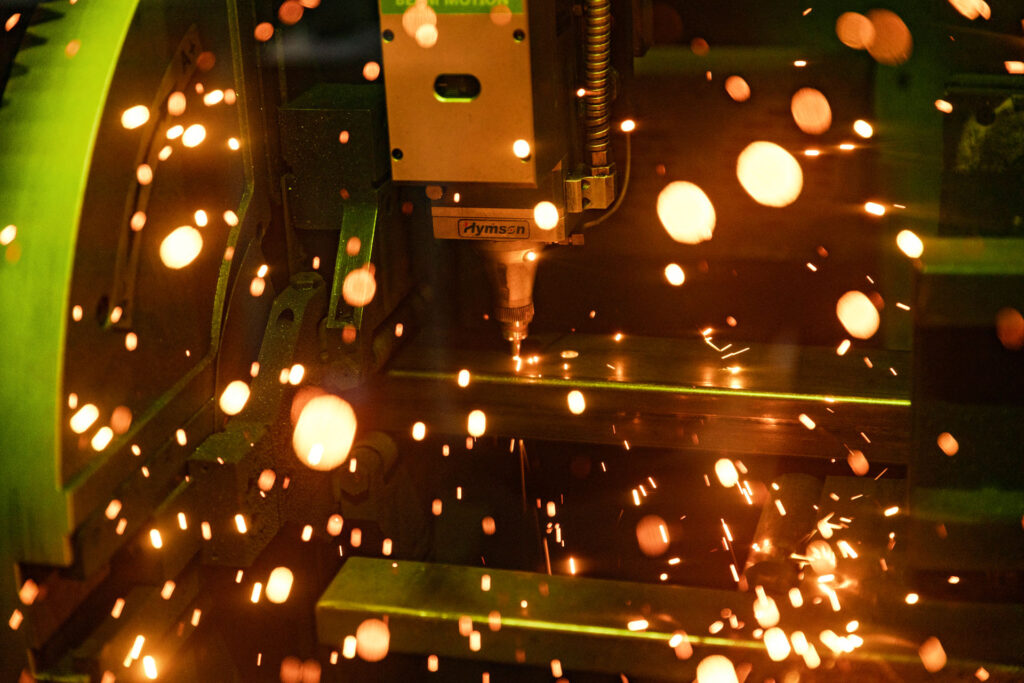

We coat the metal components of our courts with heat-cured polyester epoxy powder

This type of painting is done dry, using resin-based powders. The adhesion between the paint powder and the metal occurs thanks to the electrostatic effect that is generated between the powder and the part to be painted.

When compared with conventional paints, epoxy powder coatings provide better mechanical resistance to impact and abrasion, and greater resistance to corrosion.

Complanarity between glass elements and metal structure

We build our courts in such a way as to guarantee perfect coplanarity between the various components, to avoid steplike imperfections that could distort the bounce of the ball, as well as being dangerous for players in the event of contact with the structure.

Anti-corrosion welds

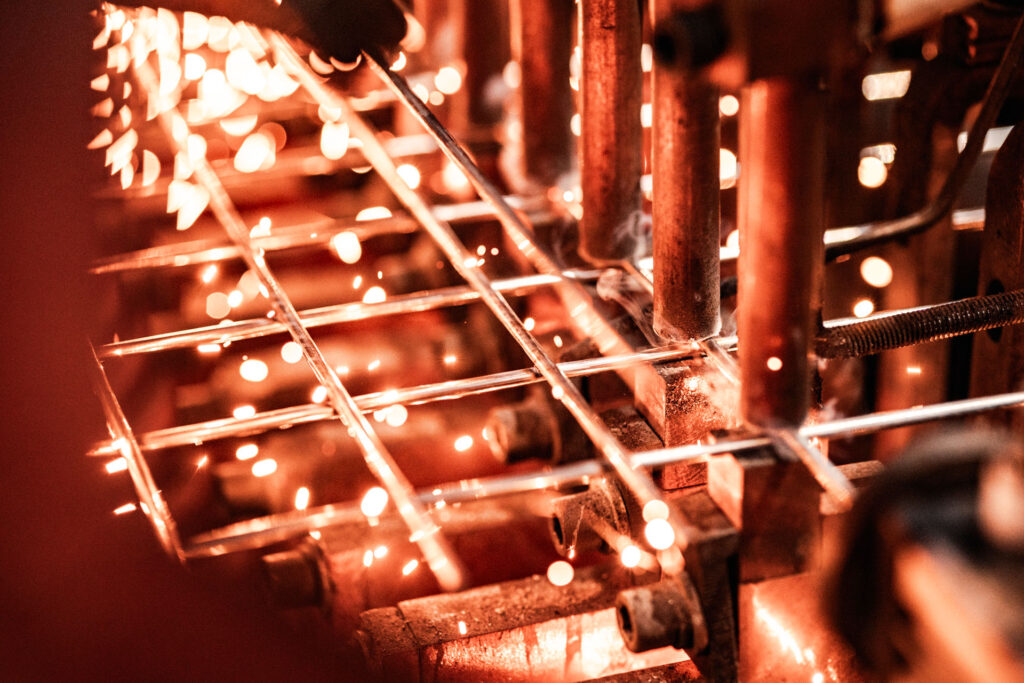

We perform the welding of our metal structures using MIG (Metal Inert Gas) technology.

This type of welding takes advantage of the action of an inert gas that protects the welding arc during the welding operation.

This process prevents the weld pool from coming into contact with the surrounding atmosphere, which could react with the weld pool itself, reducing its strength and facilitating corrosion.

The choice of wind resistance

In windy conditions, the proper sizing of padel court structures is essential to ensure the safety of the structure and users.

These regulations also provide the necessary guidance for calculating the return time, which is normally 50 years, but can be greatly reduced in the case of temporary installations.

To allow you to modulate your investment according to your real needs, without forcing you to take risks or invest in oversized structures, we have diversified our product offering to provide you with different levels of wind resistance.

All our structures intended for indoor installation guarantee wind speed resistance of 20 m/s.

This feature, irrelevant in the case of installation inside completely closed buildings, becomes extremely important in the case of installation inside buildings equipped with sliding or lifting side walls, which when open allow the wind to enter the building.

Among our structures intended for external installation, you can select the one that best meets your needs by choosing between structures that provide a resistance to wind speeds of 25, 28, 30 and 36 m/s.

The Italian Padel courts appeared on